Breaking News!

The California Trolley and Railroad Corporation (CTRC), based in San Jose, will be relocating the former Southern Pacific Railroad steam locomotive, number 2479, and the Lenzen Roundhouse structure and turntable to the Niles Canyon Railway, operated by the Pacific Locomotive Association (PLA).

Read more: Historic Locomotive and Railroad Roundhouse to Move from Santa Clara County to Niles Canyon Railway

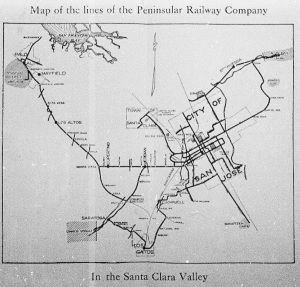

Established in 1982, CTRC, the California Trolley and Railroad Corporation, is a 501(c)(3) non-profit organization with a mission to preserve and reflect the rich legacy of rail transportation in the Santa Clara Valley for the educational and recreational benefit of current and future generations.

Rail Museum from WMS media Inc. on Vimeo.

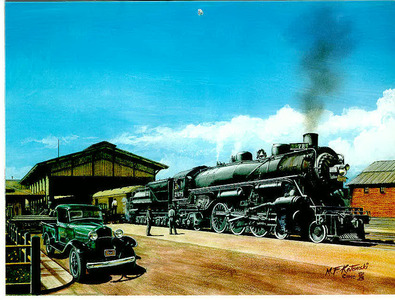

Among the numerous projects underway is the restoration of Southern Pacific steam locomotive 2479. CTRC has restored for operation a number of historic trolley cars.

The CTRC Blog contains postings and items of interest, in chronological order. Our search page is available to help you find items of intererst.

For the latest weekly updates please visit our Facebook page.

Our quarterly newsletter is The Clearboard.

A major undertaking is the creation of the San Jose Steam Railroad Museum with the focal point becoming the former six stall Lenzen Roundhouse and turntable.

Membership is open to anyone who is interested - you do not need to be an expert welder or machinist.

Please consider making a donation to CTRC. Donate!